MetLube Case Study: Aerospace Manufacturer

Customer: Large Aerospace Manufacturer

A large aerospace semi-conductor manufacturer of aircraft, aircraft engines, parts, guided missile and space vehicles and parts, was interested in improving their productivity, reducing costs and creating more efficient and sustainable operations.

Challenge

This manufacturer suffered from bacteria growth, strong sump odors, waste management issues (waste stream restrictions), extreme costs for biocide containment by using Castrol Alusol AU 39, Chevron Oil and Hangsterfers 500C.

By volume concentration during the study:

Chevron Oil… n/a

Hangsterfers 500 C … 11%

MetLube … 13%

Process and Equipment Information

Application ……………. Milling Center

Material ………………… Stainless Steel, Aluminum, Inconel

Parts …………………….. ProducedAirplane Components

Machine ……………….. Makino

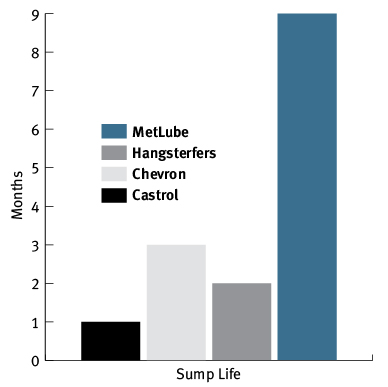

The use of MetLube increased sump life by at least 200%.

The use of MetLube increased sump life by at least 200%.Solution

MetLube metalworking fluid is a revolutionary, multi-machine, multi-application chemistry unlike any other in the industry. This unique Complex Synthetic™ technology offers substantial operational cost savings and superior performance while assuring environmental and worker safety. The interaction of this Complex Synthetic™ chemistry created superior lubricity, heat dissipation (cooling), cleaning action, corrosion and microbial life protection.

Impact and Value

⋅ Sump Life Increased by at Least 200%

⋅ Increased Sump Life to 6 Months (vs. Castrol Alusol AU 39-1 month, Chevron Oil – 3 months, Hangsterfers 500C – 2 months)

⋅ No Bacteria Growth Eliminated Odors

⋅ No Residue on Parts

⋅ Compatible with Waste Stream Restrictions

⋅ Improved Environmental and Worker Safety

⋅ Eliminated Use and Cost of Hazardous Materials