MetLube Case Study: Aerospace Manufacturer

Customer: Large Aerospace Manufacturer

A large aerospace semi-manufacturer of aircraft, aircraft engines, parts, guided missile and space vehicles and parts was interested in improving their productivity, reducing costs and creating more efficient and sustainable operations.

Challenge:

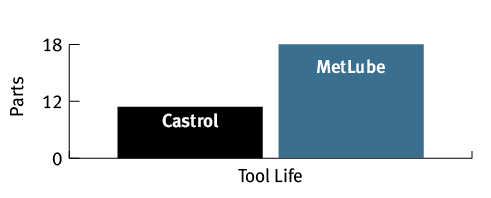

This manufacturer suffered from short tool life with replacements happening every 12 parts using Castrol Alusol AU 39 in a Makino A88.

By volume concentration during the study:

Castrol Alusol AU 39 … 11%

MetLube … 13%

Process and Equipment Information

Application CNC …………. Machine Center

Material ……………………… Aluminum, Stainless Steel

Parts ………………………….. Produced Airplane Components

Machine …………………….. Makino A88

The use of MetLube increased tool life significantly.

The use of MetLube increased tool life significantly.

Solution

MetLube metalworking fluid is a revolutionary, multi-machine, multi-application chemistry unlike any other in the industry. This unique Complex Synthetic™ technology offers substantial operational cost savings and superior performance while assuring environmental and worker safety.

The interaction of this Complex Synthetic™ chemistry created superior lubricity, heat dissipation (cooling), cleaning action, corrosion and microbial life protection.

Impact and Value

⋅ Tool Life Increased more than 50%

⋅ Increased Tool Insert Life to 18 Parts

⋅ Reduced Inventory Purchasing/Overall Cost Reduction

⋅ Reduced Waste Treatment Costs

⋅ Increased Productivity

⋅ Reduced Downtime for Tool Changes

⋅ Improved Operator Safety

⋅ Improved Environmental and Worker Safety