MetLube Case Study: Gun Manufacturer

Customer: Leading Firearm Manufacturer Based in New England

A leading firearm manufacturer based in New England who produced firearms was interested in improving their productivity, reducing costs and creating more efficient and sustainable operations.

Challenge

This manufacturer needed to eliminate outdated oil based machining that was creating unsafe work environments and extreme air quality challenges, as well as high scrap rate. The coolant being used, Fuchs, was a product specifically designed for this company, and created pain points in their production process that had to be tolerated, or have extensive workarounds built to complete the work.

By volume concentration during the study:

Fuchs ……. 10%*

MetLube … 15%

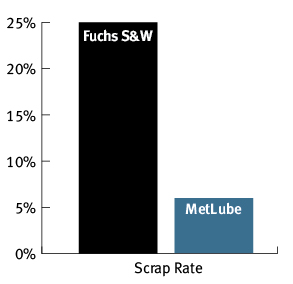

*Limits in capability due to inability to increase concentration above 10%Scrap rate based on surface finish:

Fuchs… 25%

MetLube … 6%

Process and Equipment Information

Application …………… Reaming

Material ……………….. Stainless Steel

Parts ……………………. Produced Revolver Cylinder

Machine ………………. Tsugami Machining Center

The use of MetLube reduced scrap rate by 76%.

The use of MetLube reduced scrap rate by 76%.

Solution

MetLube metalworking fluid is a revolutionary, multi-machine, multi-application chemistry unlike any other in the industry. This unique Complex Synthetic™ technology offers substantial operational cost savings and superior performance while assuring faster speed rates and environmental and worker safety.

The interaction of this Complex Synthetic™ chemistry created superior lubricity, heat dissipation (cooling), cleaning action, corrosion and microbial life protection.

Impact and Value

⋅ Extended System Life by 400%

⋅ Less Concentrate to Replenish

⋅ No Residue on Parts

⋅ Eliminated Odor

⋅ Cleaner Working Environment